- On sale!

By buying this product you can collect up to

51

points.

Your cart will total 51

points that can be converted into a voucher of

€7.65.

By buying this product you can collect up to

51

points.

Your cart will total 51

points that can be converted into a voucher of

€7.65.

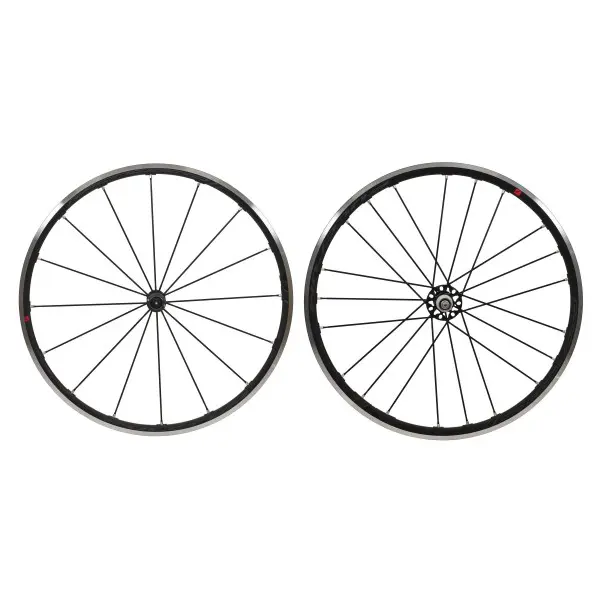

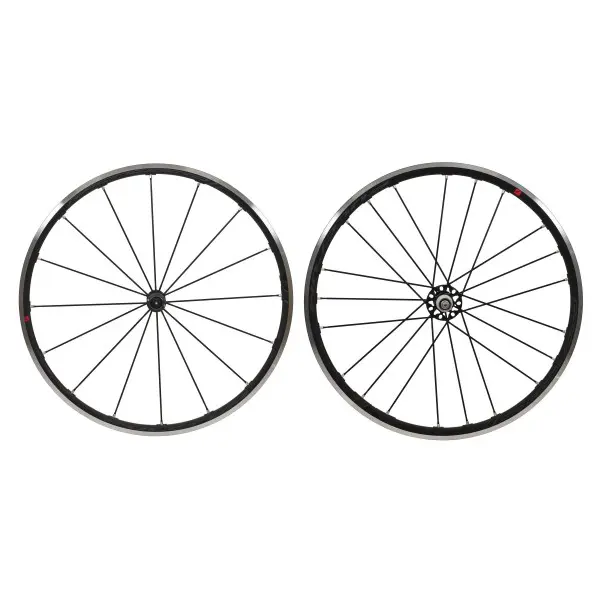

Brand- Fulcrum

Fulcrum Zero Wheels C17 2WF

With the unmistakable character that everyone knows well, the absolute ability to transmit your energy on the asphalt, its extreme driving precision.

Unparalleled in the middle of the group: they are the ideal wheels for your racing bike if you are looking for extraordinary performance and strong aesthetic characterization. The Racing Zero are the real reference point for cyclists.

The "Zero", race after race, have become synonymous with excellence, quality, performance, reliability... and now also tubeless!

2-Way Fit |

Tubeless technology was adopted in the automotive industry, then in the motorcycle industry and finally in cycling. After the debut with mountain biking it's time to "put it on the road": and that's what Fulcrum offers us. It has developed 2-Way Fit™ technology to ensure the perfect compatibility of their tubeless rims even with normal tires and inner tubes. The 2-Way Fit™ wheels are perfectly versatile to face any situation. Thanks to a particular imprint in the valve area, the assembly of the air chambers takes place with maximum precision, keeping the chamber inside the clincher perfectly stable. Even the valve for tubeless covers is housed without risk, with the undoubted advantage that there are never air infiltrations due to a non-optimal positioning at the time of assembly. The advantages are clear: the various tests have shown an unprecedented increase in smoothness. Since there is no air chamber, in fact, friction due to friction with the cover is eliminated and the perfect adherence of the clincher on the rim avoids energy dispersion. A tubeless tire does not suffer from sudden sagging in the event of a puncture, therefore, a nice advantage in terms of safety. No risk of pinching, then, because there is no inner tube to break.

RDB™ Rim Dynamic Balance |

The concept is as simple as it is ingenious: balance the mass of the rim joint with a mass of equal value positioned exactly on the opposite side.

USB™ - Ceramic Ultra Smooth Bearings™

Fulcrum® has always been recognized for the very high performance of smoothness and reliability of its hubs.

This is because all the projects are developed internally in the R&D department Fulcrum® and every detail is taken care of in a maniacal way.

Hubs equipped with USB™ ceramic bearings (Ultra Smooth Bearings) raise the level of wheel smoothness even further and reduce weight and maintenance, making your racing bike wheels loyal allies.

2:1 Two to One

When pushing on the pedals, the rotation of the sprocket pack causes a loosening of the freewheel spokes with the consequent loss of tension of the rims, regardless of the type of wheels: racing, mtb, cyclocross or triathlon.

This translates into an excessive bending of the whole and an inevitable dispersion of energy. ® Fulcrum has solved this classic cycling problem with its 2:1 Two-to-One™ Spoke Ratio patent, i.e. doubling the spokes in critical areas.

MoMag™

Mounting Magnet

What is MoMag™? A magnet and a lot of ingenuity. Thus was born the patent of the proven "Mounting Magnet" system, or the MoMag™. How does that work? The nipples, once inserted inside the circle through the valve hole, are "guided" to the hooking point with the beam through the magnet. With this simple and ingenious trick you can get a wheel without holes on the upper deck, but with spokes tensioned by traditional nipples! Advantages: no hole on the rim means having a homogeneous circle at every point, without critical points or breaking areas and, for clincher profiles, the Rim Tape is not necessary, to the advantage of weight. The advantages are immediately understandable: longer rim life, greater resistance to fatigue, possibility of tensioning the spokes more and greater rigidity which, in terms of performance, mean greater reactivity and acceleration. But that's not all. The advantages are also in favor of extremely simple and fast maintenance or replacement of the beams. All for the benefit of the cyclist who has chosen Fulcrum®.

Anti-Rotation System™

This new system dedicated to racing bike wheels takes the concept of spoke to a new level of performance.

The Fulcrum® engineers have in fact redesigned spokes and hub seats in order to create a solid and immovable whole. In this way the rays:

a) they never lose their initial tension, thus keeping the wheel perfectly reactive and centered;

(b) remain in the position studied in the vento tunnel to ensure the best possible aerodynamic penetration.

F.I.C. Fulcrum Identification Card - 100% Handmade Quality

Fulcrum, since its inception, is characterized by a feature that continues to this day: designing, prototyping and industrializing all types of wheels marked with the red "F", whether they are wheels for racing bikes, mtb wheels, cyclocross wheels or for triathlon races.

These, in fact, take shape within the innovative R&D, the advanced department that represents the beating heart of the Italian company.

Every single component of the wheels, the materials chosen and the technologies applied are the tangible result of the effort that Fulcrum® makes every day to give you maximum performance and reliability.

Traceability

A guarantee of quality. The key word for Fulcrum products is: traceability.

All Fulcrum® wheels, of any type (for racing bikes, mtb or cyclocross) are equipped with a small label. Do not remove it: it is essential to give you the guarantee that, in case of ascertained defectiveness of a production batch, your component or your wheel will be traceable.

All this because Fulcrum®, faithful to its mission, demands absolute perfection for its product and safety for its customer.

Square Milling

For the aluminium rim of the new Racing Zero, it was decided to confirm the triple milling structure throughout the profile to minimise aluminium thicknesses.

After that, the technicians added a three-dimensional milling in the base of the spokes: this means less material and the same reliability as the forces, with this particular design, are well distributed on the rim.

Triple milling and "Square Milling" allow maximum reduction of the peripheral weight of the rim, to make the wheel extremely responsive.

Differentiated Rim Height

Two different heights between front and rear: a more complex solution in terms of construction but necessary when looking for the maximum.

The front more basso serves to enhance the handling by limiting the weight as much as possible and therefore the masses involved in steering and raising.

At the rear we find a higher and granitic rim, to transmit all the power to the wheel and increase stability.

Carbon hubs

In line with the goal of saving every gram possible and choosing the most technologically advanced solutions, the R&D department has developed a seamless carbon hub.

The chosen fiber is woven at 90 degrees to better balance the torsional forces involved during pedaling.

Plasma freehub

The plasma treatment makes the aluminum particularly duro and resistant to abrasion and surface wear. This has made it possible to reduce the thickness of the material to a minimum to the advantage of the weight while preserving durability and reliability.